UV Cure

Clean Parts, Flawless Finishes The Crucial Step in 3D Printing

Our advanced part washing solutions go beyond a simple rinse. They are a critical step in a professional workflow, designed to guarantee your parts meet the highest standards of quality, finish, and performance. Part washing is the bridge between a raw, printed part and a finished, functional product. Our systems are engineered for precision, meticulously removing uncured resin, residual powders, and support material debris. This isn't just about cleanliness; it's about preparing your parts for what comes next. By eliminating all contaminants, we ensure superior adhesion for coatings, paints, and finishes, leading to a flawless final product that looks and performs exactly as intended.

Manual part cleaning is slow, inconsistent, and can introduce human error. Our automated solutions eliminate these challenges. With programmable wash cycles and custom settings, you can process multiple parts simultaneously, freeing up your team to focus on more complex tasks.

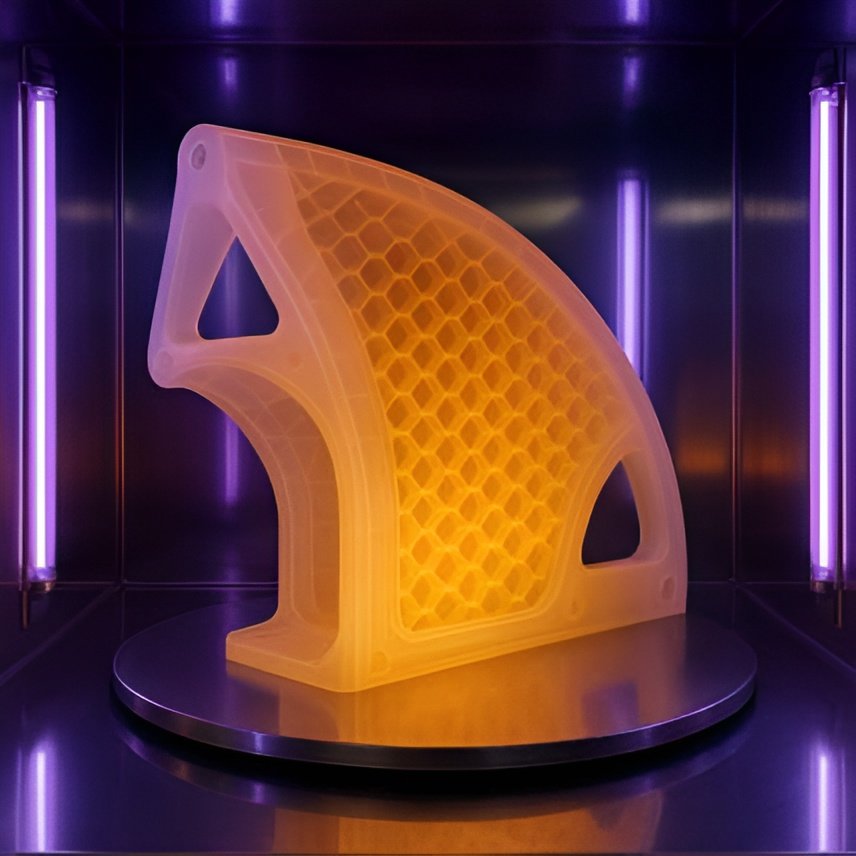

UV Curing Chamber – Precision Post-Processing for 3D Printing

UV curing chambers play a critical role in the post-processing stage of 3D printing by exposing printed parts to carefully controlled ultraviolet light. This process initiates a chemical reaction within the resin material, fully curing it to achieve the intended strength and durability. By completing polymerization, the chamber not only improves the mechanical properties of the part—such as toughness, stability, and resistance to wear—but also enhances its visual quality, delivering smoother surfaces and a professional finish. The result is a 3D-printed component that is not only functional but also reliable for demanding industrial applications.

By strengthening and finalizing each part, UV curing chambers ensure that your printed components are not only visually refined but also mechanically optimized for long-term performance in industries ranging from healthcare and automotive to aerospace and manufacturing.

Why Part Washing Is More Than Just a Rinse

Part washing isn’t optional—it’s an essential stage of industrial 3D printing. It ensures your parts meet the highest standards of quality and durability.

Improves Part Quality

Smooth, residue-free surfaces enhance performance and aesthetics.

Enhances Post-Processing

Prepares parts for painting, coating, or final assembly.

Increases Durability

Prevents residue buildup that can weaken parts over time.

Boosts Efficiency

Automates a manual, time-consuming step for faster workflows.

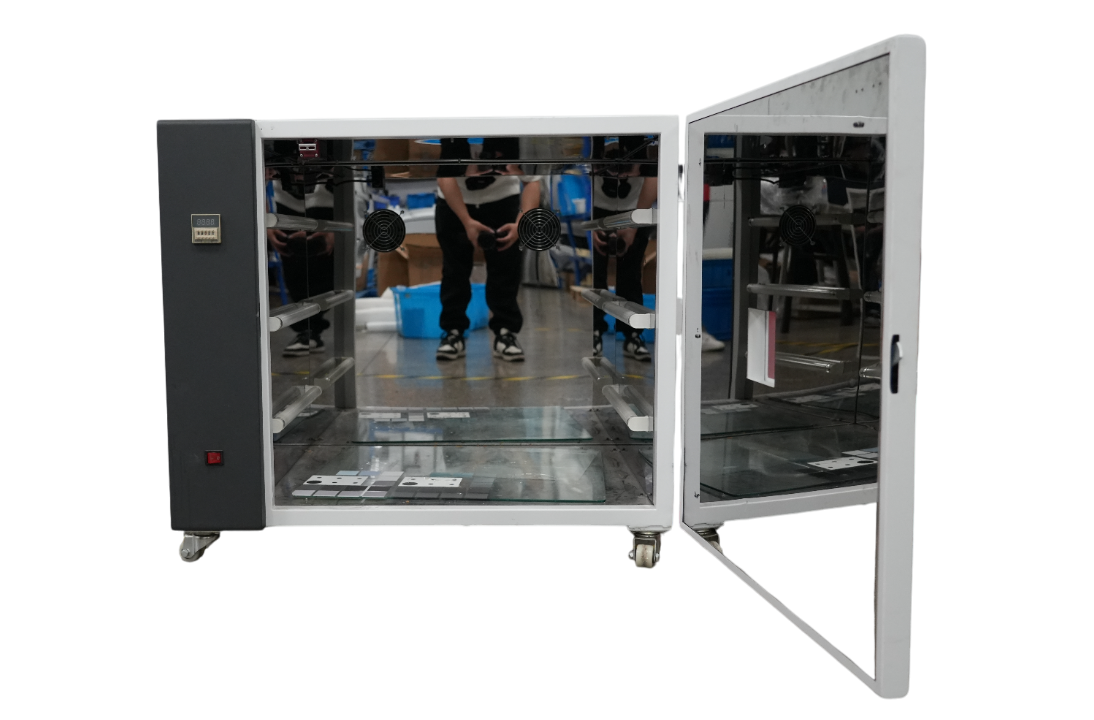

UV Cure 600 – Compact UV Curing Chamber for 3D Prints

The UV Cure 600 is a state-of-the-art UV curing chamber designed to deliver high-precision, efficient post-processing for your 3D printed parts. Whether you're working with resin-based prints or complex models requiring fine detail, this chamber ensures optimal curing, enhancing both the aesthetic and mechanical properties of your prints.

UV Cure 1600 – Industrial UV Curing Chamber for 3D Printing

For those requiring a higher level of precision and speed in the post-processing phase of 3D printing, the UV Cure 1600 is the ideal solution. Designed for industrial-scale operations and large-format prints, this cutting-edge curing chamber boasts an advanced UV light system and enhanced features that cater to even the most demanding 3D printing projects.

Why Part Washing Is More Than Just a Rinse

Designed for speed, safety, and precision—our washing systems help manufacturers consistently achieve clean, production-ready parts.

EcoWash Pro

- Uses eco-friendly solvents to reduce environmental impact.

- Automated cleaning cycles for consistent, hands-free operation.

- Compatible with polymers, resins, and metals.

- Energy-efficient design lowers operating costs.

- Compact footprint, perfect for labs and small production floors.

- Customizable wash settings to suit different geometries.

- Low-maintenance system with long-lasting components.

PowerClean Max

- Designed for large or complex industrial parts.

- High-performance cleaning for heavy-duty applications.

- Compatible with multiple industrial materials.

- Robust construction for continuous, demanding use.

- Advanced cycle control for precise cleaning results.

- Fast throughput, reducing bottlenecks in production.

- Enhanced safety features to protect operators in high-volume environments.