Smart Series

SMART Series

Next-Generation Precision & Efficiency

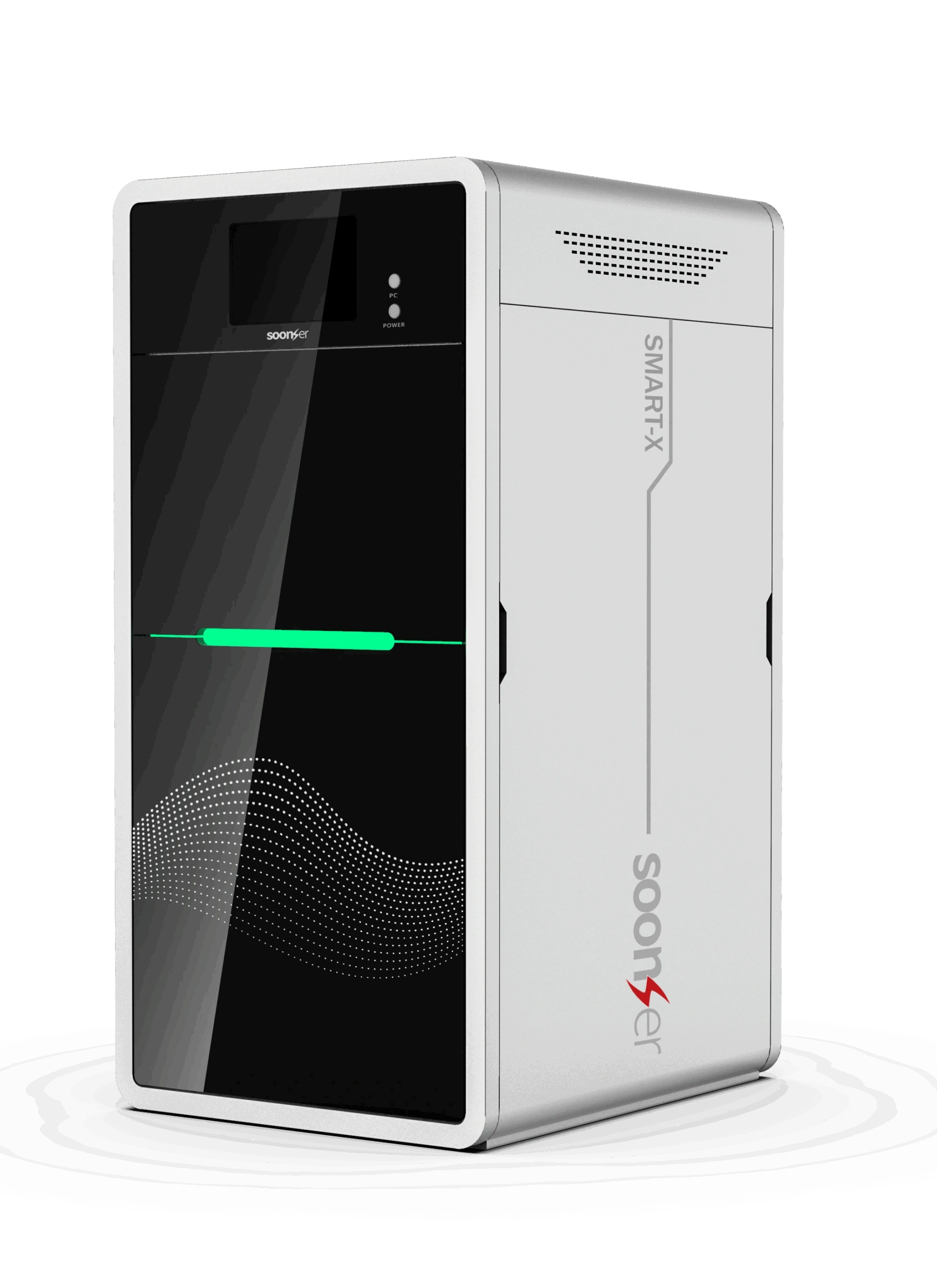

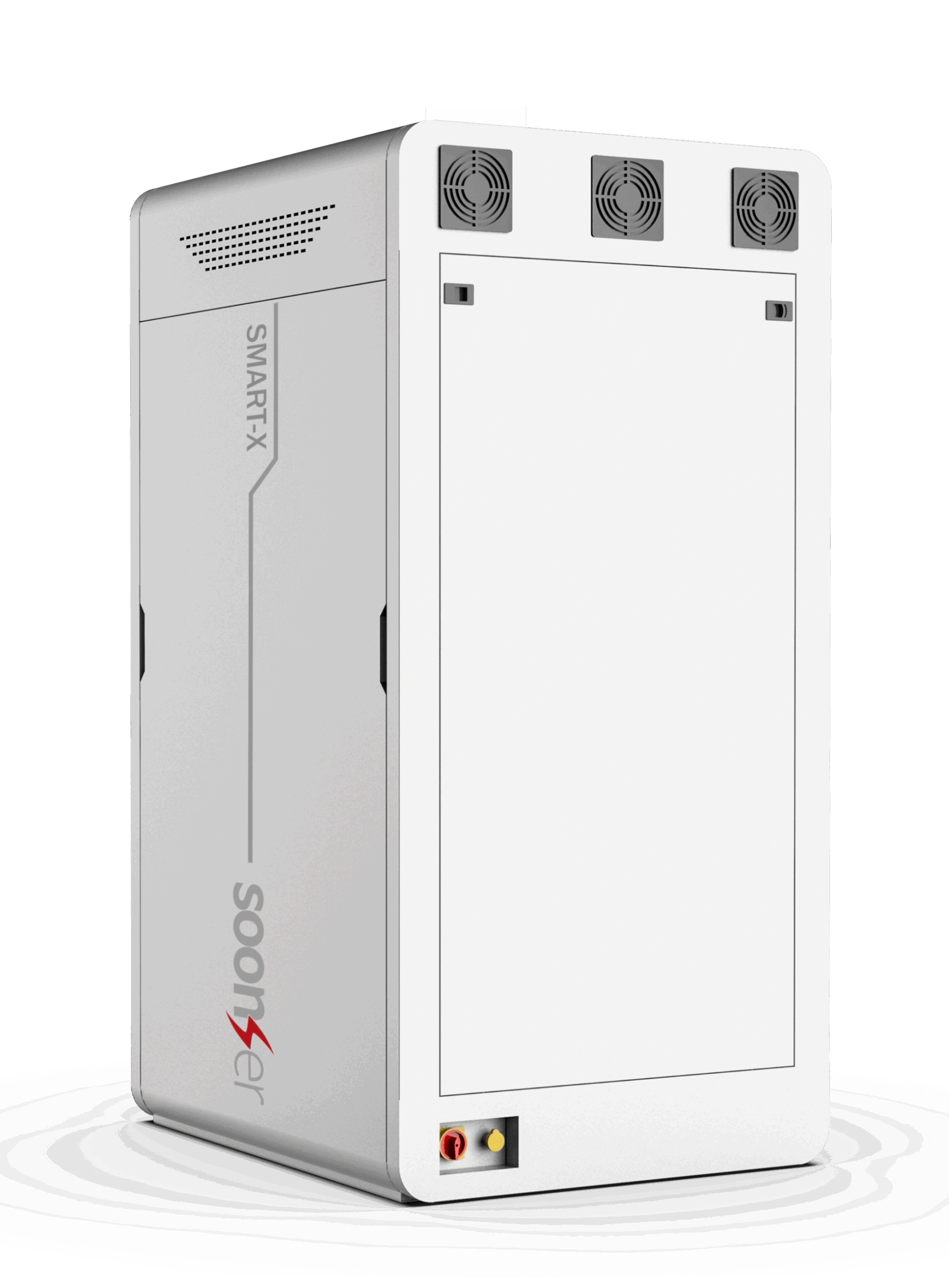

The SMART Series 3D Printers redefine industrial 3D printing with an intelligent balance of speed, precision, and reliability. Designed for professionals who demand high-performance additive manufacturing, the SMART-300H and SMART-400H deliver consistent, high-quality prints while maximizing efficiency and ease of use.

Key Benefits :

- Optimized Print Volume – SMART-300H: 300x300x250mm, SMART-400H: 400x400x300mm, ideal for a wide range of applications.

- High-Speed Performance – Advanced motion control ensures rapid, precise printing with scan speeds of 6-15m/s.

- Industrial-Grade Precision – Accuracy of ±0.1mm (L<100mm); ±0.1% x L (L≥100mm) for superior quality.

- Smart Auto-Leveling – Fully automated bed leveling ensures hassle-free setup and repeatability.

- Robust Build Quality – Durable metal frame construction for maximum stability and longevity.

- Multi-Material Compatibility – Supports resin-based materials for a variety of industrial applications.

- User-Friendly Touchscreen Interface – Intuitive UI for easy operation and real-time monitoring.

Technical Specification

Build Volume

SMART-300H: 300x300x250mm | SMART-400H: 400x400x300mm

Layer Thickness

0.05mm – 0.2mm (Optional)

Scan Speed

Typical speed 6-15m/s

Print Efficiency

50-100g/h

Spot Mode

Fixed spot

Spot Size

0.08mm

Printer Dimensions

800mm x 980mm x 1750mm (W x D x H)

Printer Weight

350KG (Without Resin)

Power Requirements

200-240VAC, 50/60Hz, Single phase 1.2kW

Why Choose

Why Choose the SMART Series?

Value-Driven Performance

Unparalleled Value – High-end industrial features at an unbeatable price point.

Built For Reliability

Reliability You Can Trust – Built to handle long print cycles with minimal maintenance.

Intelligent Automation

Intelligent Features – Smart auto-leveling and a robust UI make printing effortless.

Scalable Smart Solutions

Scalable Solutions – Whether you’re a small business or a large enterprise, the SMART Series adapts to your production needs.

Ideal Applications

The SMART Series is designed for engineers, designers, manufacturers, and educators who need a cost-effective yet powerful industrial-grade 3D printing solution. Common applications include:

Rapid Prototyping

Quickly iterate and refine designs with high-detail prototypes.

End-Use Production Parts

Print strong, functional components for real-world applications.

Tooling & Jigs

Create custom fixtures and tools to improve workflow efficiency.

Educational & Research Use

A versatile, easy-to-use system for STEM education and advanced research.

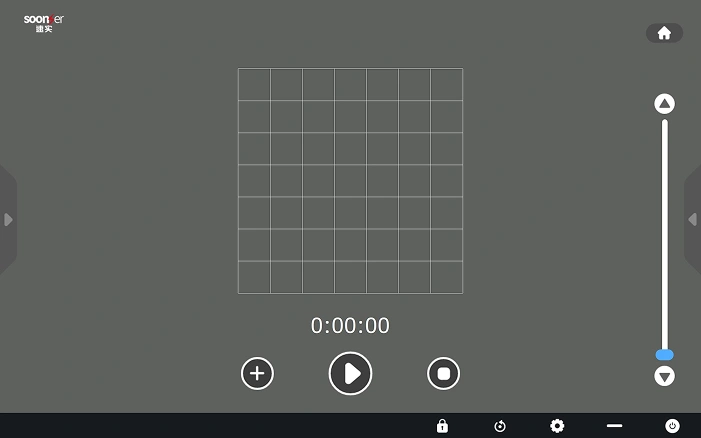

AsterRay Control Software Introduction

Main Interface and Subregion of Software

The main interface mainly includes the left menu bar, the bottom shortcut toolbar, the two-dimensional display area after model slicing, and the right real-time information display window.

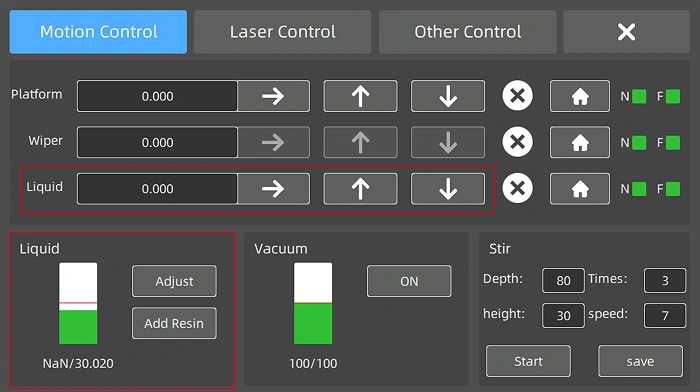

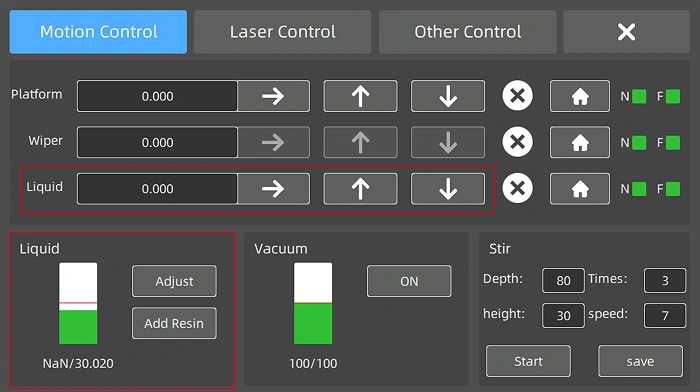

Three axis motion control interface

Return Home Calibration : the return home process is an important step for the software to determine the coordinate system. If someone intervenes with the hardware device during the shutdown, be sure to click the return home button

after the next startup to return the system to its original state. In the process of returning to the original system, return the scraper, liquid level slider and grid plate to zero to reposition the hardware.

Level Control Interface

This interface allows users to monitor and adjust the resin level, control vacuum adsorption, and configure sampling parameters.

Use "Add Resin" to refill, "Resin Level Adjustment" to set targets, and start vacuum or sampling as needed.

All functions help ensure stable and precise conditions before printing.

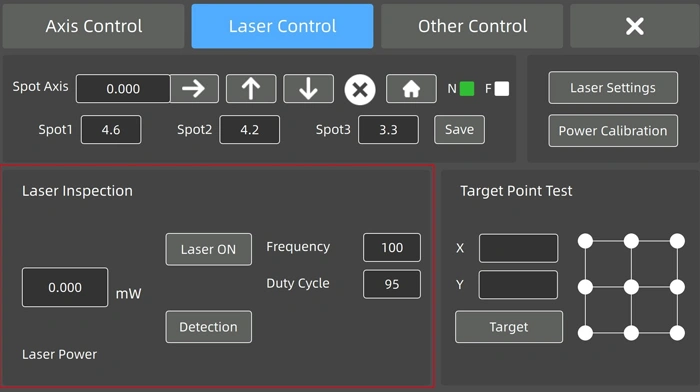

Laser Power Adjustment Interface

a.The laser frequency is the recommended working frequency in the laser instruction manual, which should be configured according to the laser instruction manual, and should not be changed at will.

b.The value of duty cycle is 0~100%, which represents the percentage of output power and maximum power. The output power can be adjusted by changing the duty cycle.

Get Started Today!

Experience the power of industrial-grade 3D printing with the SMART Series.