Mars Pro 600

Mars Pro 600

High-Performance Industrial SLA Printing

The Mars Pro 600 is a next-generation industrial SLA 3D printer engineered for large-format, high-precision additive manufacturing. Featuring an expansive 600 × 600 × 400 mm build area, advanced scanning technology, and exceptional accuracy, it’s the ultimate solution for functional prototyping, tooling, and end-use part production. Designed for industries that demand speed, consistency, and scalability, the Mars Pro 600 redefines industrial-grade 3D printing.

Key Benefits :

- Ultra-Precise Printing – Achieves high accuracy of ±0.001” (L < 1”), ±0.1%L (L ≥ 4”), ensuring flawless part quality.

- Expansive Build Volume – 600 × 600 × 400 mm (24 × 24 × 16”), ideal for large-scale prints and batch production.

- Vario Scan Spot Sizing – Adjustable spot size from 0.08 – 0.80 mm, optimizing speed and resolution.

- Industrial-Grade Components – Equipped with Germany Scanlab Galvanometer, AOC Lasers, THK Precision Modules, and F-Theta Lenses for superior stability and performance.

- Robust & Stable Design – Grade 00 Marble Platform minimizes vibrations, while the one-piece frame structure ensures long-term durability.

- Optimized Workflow & Connectivity – Supports .STL, .SLC, and .CLI file formats, ensuring compatibility with industry-leading software.

- Energy-Efficient & High-Output – Operates on 200-240 VAC, 50/60 Hz, Single Phase, 2.5 kW, balancing performance and efficiency.

Technical Specification

Build Area

600 × 600 × 400 mm (24 × 24 × 16”)

Accuracy

±0.001” (L < 1”), ±0.1%L (L ≥ 4”), ±0.1 mm (L < 100 mm), ±0.1%L (L ≥ 100 mm)

Spot Size

0.08 – 0.80 mm (Vario Scan)

File Formats

STL, .SLC, .CLI

Printer Dimensions

1520 × 1320 × 1970 mm (59.8 × 52 × 77.6”)

Printer Weight

1000 kg (2200 lbs) (without resin)

Power Requirements

200-240 VAC, 50/60 Hz, Single Phase, 2.5 kW

Why Choose

Why Choose the Mars Pro 600?

High-Speed Production

Advanced Industrial SLA Technology – A high-speed, ultra-precise 3D printing solution designed for large-scale production.

Built For Reliability

Reliability & Longevity – Built with premium components from industry leaders like Schneider, Omron, and Delixi for unmatched durability.

Seamless Integration

Seamless Integration – Fully compatible with standard industry workflows, optimized for high-efficiency production environments.

Proven Performance

Trusted by professionals in engineering, aerospace, medical, and manufacturing industries.

Ideal Applications

The Mars Pro 600 delivers industrial-grade SLA printing for engineers, manufacturers, educators, and researchers, enabling scalable, precise, and versatile applications.

Automotive & Aerospace

Produce durable, high-precision components for functional testing and lightweight production parts.

Manufacturing & Tooling

Rapidly create custom jigs, fixtures, and end-use components using industrial-grade materials.

Medical & Dental

Print biocompatible parts, prosthetics, and intricate surgical models with exceptional accuracy.

Consumer Prototyping

Develop high-fidelity prototypes and short-run production parts with superior surface quality.

AsterRay Control Software Introduction

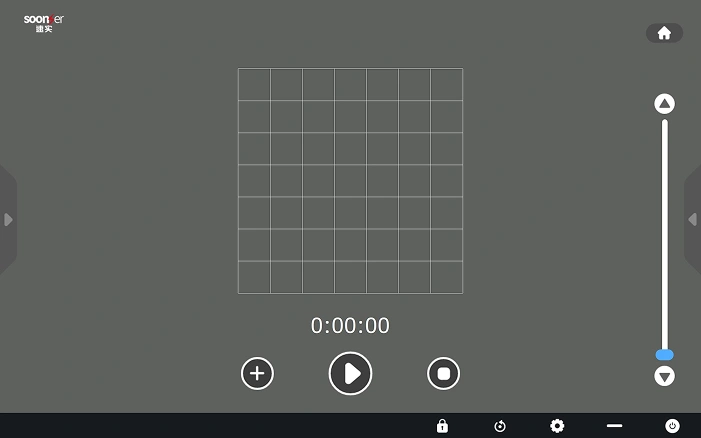

Main Interface and Subregion of Software

The main interface mainly includes the left menu bar, the bottom shortcut toolbar, the two-dimensional display area after model slicing, and the right real-time information display window.

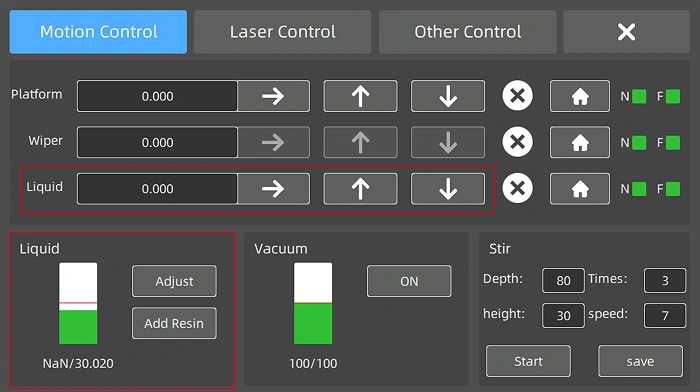

Three axis motion control interface

Return Home Calibration : the return home process is an important step for the software to determine the coordinate system. If someone intervenes with the hardware device during the shutdown, be sure to click the return home button

after the next startup to return the system to its original state. In the process of returning to the original system, return the scraper, liquid level slider and grid plate to zero to reposition the hardware.

Level Control Interface

This interface allows users to monitor and adjust the resin level, control vacuum adsorption, and configure sampling parameters.

Use "Add Resin" to refill, "Resin Level Adjustment" to set targets, and start vacuum or sampling as needed.

All functions help ensure stable and precise conditions before printing.

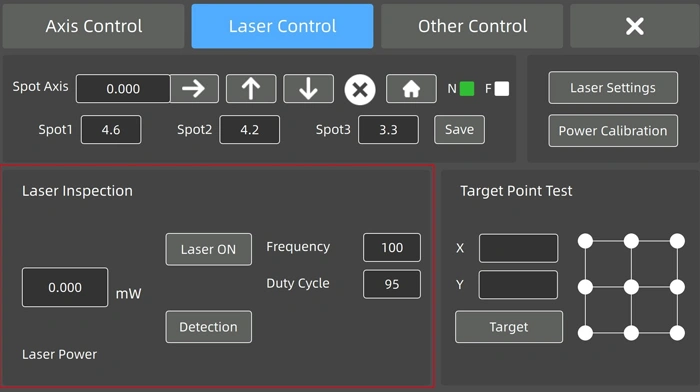

Laser Power Adjustment Interface

a.The laser frequency is the recommended working frequency in the laser instruction manual, which should be configured according to the laser instruction manual, and should not be changed at will.

b.The value of duty cycle is 0~100%, which represents the percentage of output power and maximum power. The output power can be adjusted by changing the duty cycle.

Get Started Today!

Experience the power of industrial-grade 3D printing with the Mars Pro 600.