Software

AsterRay Control Software Introduction

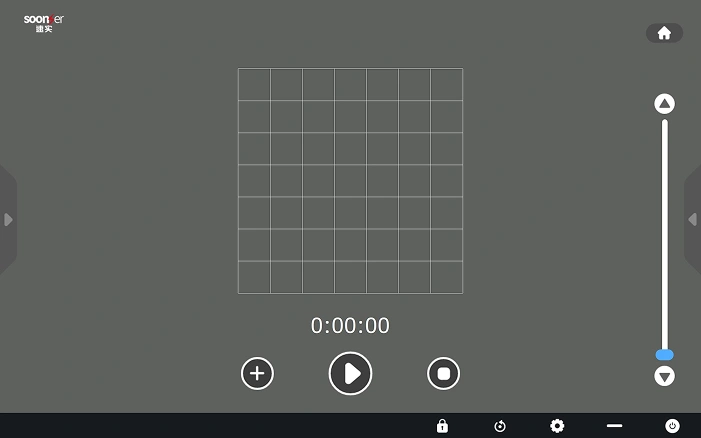

Main Interface and Subregion of Software

The main interface mainly includes the left menu bar, the bottom shortcut toolbar, the two-dimensional display area after model slicing, and the right real-time information display window.

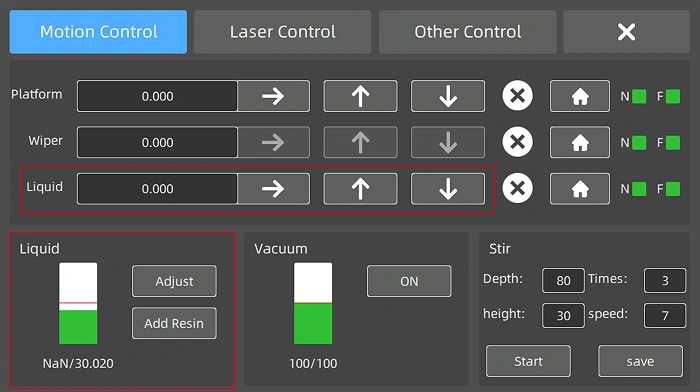

Three axis motion control interface

Return Home Calibration : the return home process is an important step for the software to determine the coordinate system. If someone intervenes with the hardware device during the shutdown, be sure to click the return home button

after the next startup to return the system to its original state. In the process of returning to the original system, return the scraper, liquid level slider and grid plate to zero to reposition the hardware.

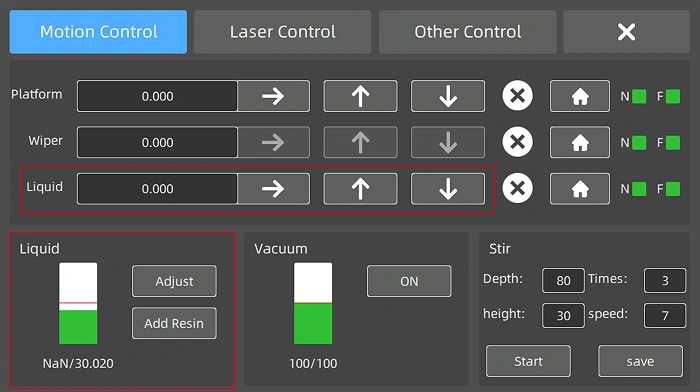

Level Control Interface

This interface allows users to monitor and adjust the resin level, control vacuum adsorption, and configure sampling parameters.

Use "Add Resin" to refill, "Resin Level Adjustment" to set targets, and start vacuum or sampling as needed.

All functions help ensure stable and precise conditions before printing.

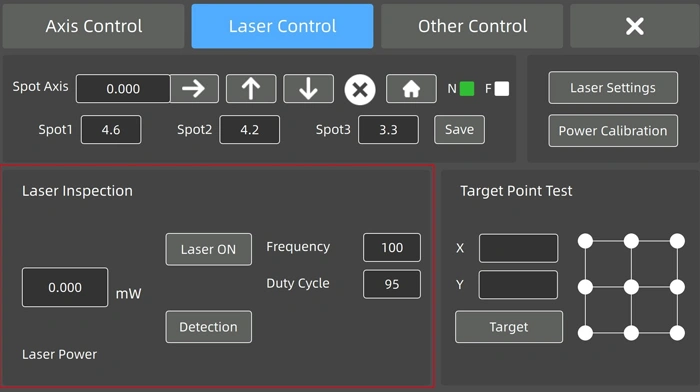

Laser Power Adjustment Interface

a.The laser frequency is the recommended working frequency in the laser instruction manual, which should be configured according to the laser instruction manual, and should not be changed at will.

b.The value of duty cycle is 0~100%, which represents the percentage of output power and maximum power. The output power can be adjusted by changing the duty cycle.

Key Advantages of SoonSer AsterRay

High Efficiency

AsterRay outperforms standard market software in printing efficiency, significantly reducing print time compared to other products on the market.

User-Friendly Interface

The software features a clean, intuitive interface, making it easy for engineers to operate and navigate.

Dedicated Support

From consultation to after-sales support, we ensure that our customers succeed.